Retrofit

In factories, production equipment, such as machines, is often used intensively and suffers from the wear and tear of time. As a result, breakdowns become more frequent. While replacing a small machine is usually quite straightforward, it is a different matter for automated lines, especially when they represent significant investments.

Are you facing this issue with an older piece of equipment? There are solutions to modernize your equipment, particularly through retrofit.

What is RETROFIT?

Retrofit is an approach that extends the lifespan of industrial machines by giving them a second life.

In practice, it involves modernizing an existing machine by replacing outdated components with new equipment, integrating cutting-edge technologies. This may include advanced features such as:

- Communication with management software (ERP) for better data tracking.

- More accurate diagnostics in case of breakdowns, reducing downtime.

Whether driven by a breakdown or not, retrofit can be prompted by the obsolescence of parts or difficulties in maintaining a relationship with the original supplier (who may no longer be in business), limiting the possibilities for upgrading or repairing the machine.

The modification can be either partial or complete depending on technical needs or constraints:

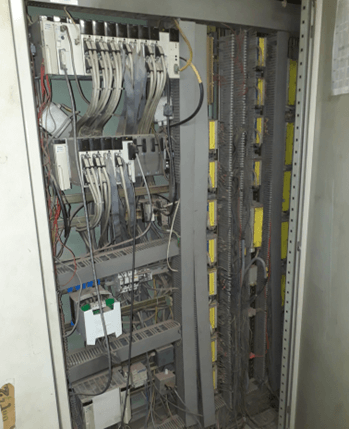

- Replacement of automation hardware

- Replacement of IT hardware

In short, retrofit is a strategic solution that combines performance, durability, and cost savings in an industrial context.

Which equipment can be retrofitted?

Retrofit primarily applies to machines with a high level of technology that are subject to obsolescence. The larger and more expensive the equipment (such as fully automated and/or robotic lines), the more financially advantageous retrofit becomes.

Types of retrofit

-

AUTOMATION RETROFIT

Automation retrofit offers several significant advantages:

- Modernization of equipment: It allows for the integration of cutting-edge equipment, such as controllers or variable frequency drives, which are more efficient, quickly available when needed, and well-known to suppliers, making maintenance easier.

- Simplified Wiring: Thanks to network-connected modules, wiring is optimized, reducing complexity and associated costs.

- Increased Compatibility: In some cases, older controllers are no longer compatible with current equipment (outdated operating systems, lack of connection ports, programs stored on floppy disks, etc.). Retrofit solves these issues by modernizing these connections.

- New Features: It becomes possible to add tools such as sensors connected via IO-Link, which provide a wealth of information (temperature, wear, etc.), along with advanced machine diagnostic functions.

- Energy Management: Energy consumption measurement modules can be integrated, allowing for the analysis of energy data to optimize consumption.

In this way, even the oldest machines can benefit from modern technologies, improving their performance, maintenance, and longevity.

-

IT RETROFIT

IT retrofit, which involves the replacement of IT hardware, offers several key advantages:

- Performance and Security: It ensures the use of cutting-edge operating systems, providing greater reliability, particularly in terms of cybersecurity.

- Modern Interfaces and Connectivity: Current development tools allow for a more intuitive software interface, offering optimized displays and accurate machine data reporting. This fully aligns with the Industry 4.0 movement, with connected and intelligent machines.

- New Features: IT retrofit enables the integration of new software functionalities, such as:

- Integration with client ERPs,

- More advanced fault diagnostics,

- Automatic database backups.

Additionally, our software is compatible with most ERP systems, ensuring smooth and efficient integration.

Who to contact for equipment retrofit?

The preferred contact is the machine manufacturer itself. They possess the program sources, understand the machine's operation (cycles), and are familiar with the original project's input data.

If the connection with the original equipment supplier is broken (e.g., difficulty in reaching them or the company no longer exists), you can reach out to the TECAUMA team to discuss your needs. We will assess the project's feasibility together and deploy the solution to modernize your equipment. TECAUMA has in-house automation and IT experts capable of working on machines from other brands.

How does a retrofit work at a client's site?

- Initial Diagnostic/Expert Visit:

The retrofit process usually begins with an expert visit/diagnostic of your equipment. This visit aims to:- Determine the mechanical wear of your equipment (measurement of mechanical play),

- Check the consistency of the electrical diagrams with the actual wiring (sometimes modifications are made by the client that need to be accounted for),

- Assess the machine operation in production to understand the various constraints related to the product.

- Post-Visit Recommendations:

Following the initial assessment, a recommendation for component replacement will be made to bring the equipment's technology up to date. Depending on the situation, the proposal may include:- Automation retrofit, such as replacing an obsolete controller, HMI, or variable frequency drives,

- IT retrofit, involving the replacement of one or more PCs with updated operating software and installation of a new application.

- Planning:

Based on the level of retrofit requested by the client, a schedule is created to minimize the downtime of your machine.

- Intervention Phases:

The intervention by our technicians follows this sequence:- Disconnecting cables,

- Installing new components (automation and IT),

- Rewiring,

- Simultaneously, and to save time (during non-productive periods), the replacement of mechanical components may also be carried out,

- Manual testing of the machine's actuators,

- Limited production testing,

- Full production testing over 1 to 2 days, conducted by an automation/IT expert, to validate proper functionality.

Typically, a small week is sufficient to complete the automation and IT retrofit of an automated line.

Are there limits to Retrofit? Retrofit vs. Investment in new equipment

The advantages of retrofitting are undeniable. However, it is not always the best solution.

While retrofitting is generally less expensive than replacing a machine, several factors must be considered. If, from a financial and strategic perspective, this approach does not seem advantageous in the long term, the purchase of a new machine should be seriously considered.

Ultimately, retrofitting industrial machines is a growing trend due to its many benefits, particularly in the context of an ongoing ecological transition. Having modern and highly competitive equipment without the need for a new acquisition is undeniably appealing.

Many providers can assist you in making this choice. However, it is crucial to select a reliable and experienced partner if needed.

In conclusion, retrofit is an attractive and sustainable option, particularly in the context of an ecological transition and the desire to avoid unnecessary acquisitions. However, if financial and strategic considerations indicate that the benefits of continued use of an outdated machine are limited, the purchase of a new machine should be seriously considered.

Choosing a qualified and trustworthy provider is essential for ensuring that retrofit decisions are made based on sound technical and financial assessments.

In Summary, the Advantages of Retrofitting:

✔️ Enhances equipment performance (energy efficiency, production speed, etc.).

✔️ Reduces environmental impact by acting as a form of industrial recycling, giving your equipment a new lease on life (or at least extending it).

✔️ Saves on maintenance costs and minimizes production downtime.

✔️ Increases operational flexibility.

✔️ Improves workplace safety and enhances employee comfort.

To move toward a more efficient, cutting-edge, and environmentally friendly industry, choose retrofitting solutions as your path to innovation.

Testimonial from SVC/ODS

Following the automation and IT retrofit of their sheet metal storage system:

(English subtitles available on YouTube)