Brickworks & Tile factory

Since the 1980s, TECAUMA has been alongside tile and brick manufacturers by offering handling equipment for these clay-based products at all stages of the process (green clay, dry, cooked). Alongside a world-leading group of turnkey ceramic factories for 30 years, TECAUMA have experimented its processes on all continents. Today TECAUMA accompanies leaders of the sector by using technologies that give an answer to the challenges of the fourth industrial revolution.

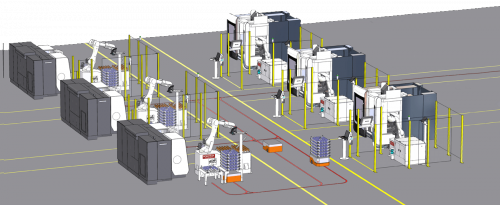

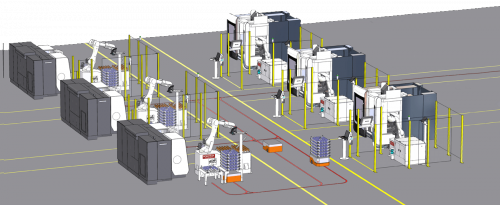

TECAUMA robotic solutions meet the criteria of high speeds (productivity), variable formats (flexibility), and appearance (quality). The user-friendly interface (piloting and supervision) of the lines keep the operators away from the arduousness.

-

TECAUMA integrates AGVs (Automated Guided Vehicules) into its handling and flow management...

TECAUMA integrates AGVs (Automated Guided Vehicules) into its handling and flow management... -

Brick cutters

The brick cutter, placed at the end of a molding machine, cuts the bricks to length and makes the necessary... -

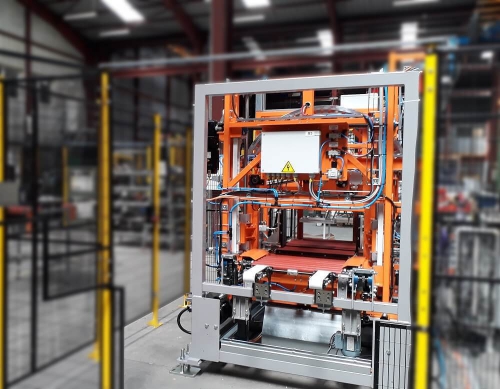

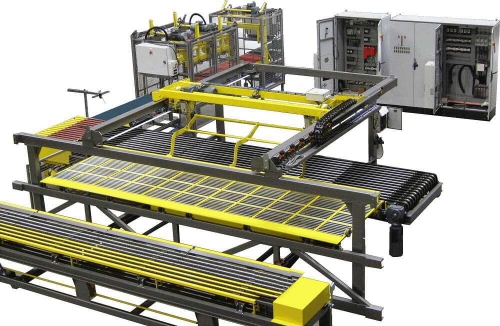

BRICK CUTTING AND LOADING MACHINE

This equipment is a green cutter after moulding, equipped with a dryer feeder, which automatically feeds... -

Packed brick unstacker

In brick factories in the Maghreb, this equipment automatically unstacks the packed bricks from the wagons,... -

Tile cutters

The tile cutter, placed at the end of the molding machine, allow you to cut spun tiles to length and to... -

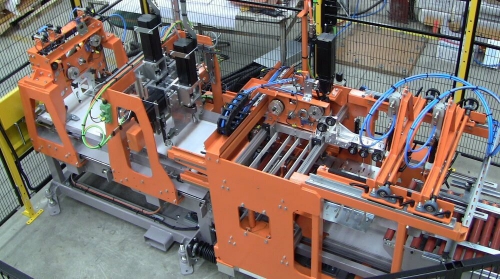

Tile loading robotic cells

TECAUMA’s robotic tile loading cells are allying flexibility of adaptation and intuitive control. They...