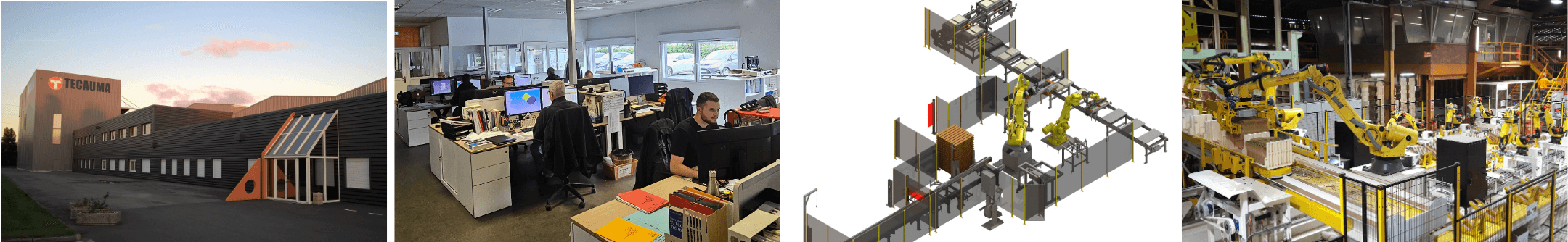

The company

Since 1977, TECAUMA has been designing, manufacturing, and installing automated and robotic handling solutions tailored to your industry. We primarily operate in three sectors: window & door manufacturing, brickwoorks and roof tile factory and metallurgy, while also addressing specific needs in other fields.

TECAUMA, Leader in Automated Production Lines and Handling Solutions

With a comprehensive range of applications in these sectors, TECAUMA offers:

- Tailored equipment solutions designed for the specific needs of these industries

- Horizontal framing machines, coupling stations and vertical storage solutions for windows and doors

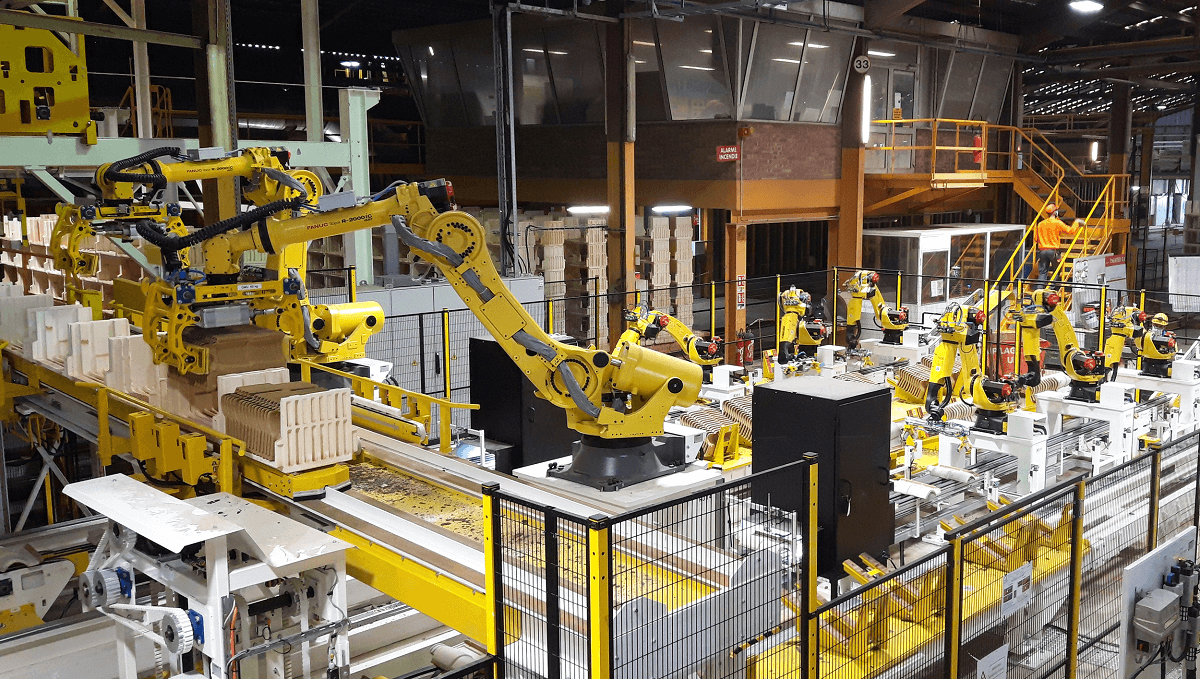

- Robotic and flexible handling solutions for brick and tile manufacturers

- Loading/unloading robots for the metallurgy sector, among others

- Robotic handling solutions that meet the highest speed and precision requirements

- Autonomous ground handling equipment (AGVs) for efficient material transport.

- User-friendly and intuitive interfaces accessible to all

- Safety solutions that comply with all applicable standards while ensuring ergonomic efficiency

Each solution developed by TECAUMA focuses on addressing both medium-term and long-term production challenges, ensuring continuous improvement and enhanced productivity for our clients.

TECAUMA: ISO 9001 Certified Quality Management System

The company employs a team of 80 professionals, equally dedicated to engineering and project implementation.

To ensure top-quality service, TECAUMA relies on:

- A team of highly skilled technicians and engineers

- Flexible, customized solutions tailored to each client’s specific needs

- Reliable after-sales service for long-term support

TECAUMA's Quality Management System is certified to AFAQ ISO 9001 (2015 version).

TECAUMA's Quality Management System is certified to AFAQ ISO 9001 (2015 version).

OVER 40 YEARS OF EXPERTISE IN AUTOMATED HANDLING SOLUTIONS

Since 1977, TECAUMA has been a leader in developing automated handling solutions, successfully delivering thousands of projects across various industries.

Our machines and automated systems are renowned for their reliability and performance, both in France and internationally.

TECAUMA consistently invests in innovation, anticipating future industry trends and developing advanced handling solutions to address the evolving challenges of manufacturers.

Our future-focused vision

At TECAUMA, customer satisfaction is at the heart of our priorities. We are committed to providing high-performance automated solutions, on time and in line with your expectations.

Our organization is based on a dual strength:

- The experience of having been part of an international group, which provides the necessary organization to manage large-scale projects and offers you the best at every phase.

- The flexibility and agility of a human-sized company, able to adapt to every situation. Our goal is to continue to maintain this organization, which is a guarantee of quality and service.

At TECAUMA, we place great importance on each member of our team. We ensure the continuous development of skills and provide support and care for those who join us. We work as a team, promote cohesion, and make sure no one is left behind, all to achieve our goal: the success of your project.

The key milestones in TECAUMA's history

TECAUMA, a company that has always been able to adapt to its clients' needs while developing new technologies:

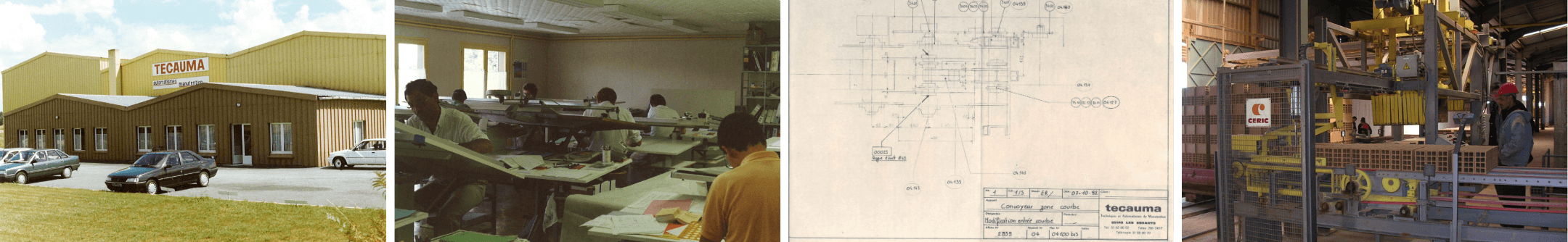

1977 to 1989

1977 - Creation of TECAUMA by Gérard HERBRETEAU in a 258m² facility. The company designs, manufactures, and installs automated handling equipment in the wood and brickworks sectors.

1980 - TECAUMA exports its first machines through its partner CERIC, a Paris-based engineering company, global specialist in turnkey factories for the production of bricks and roof tiles, which also became a shareholder.

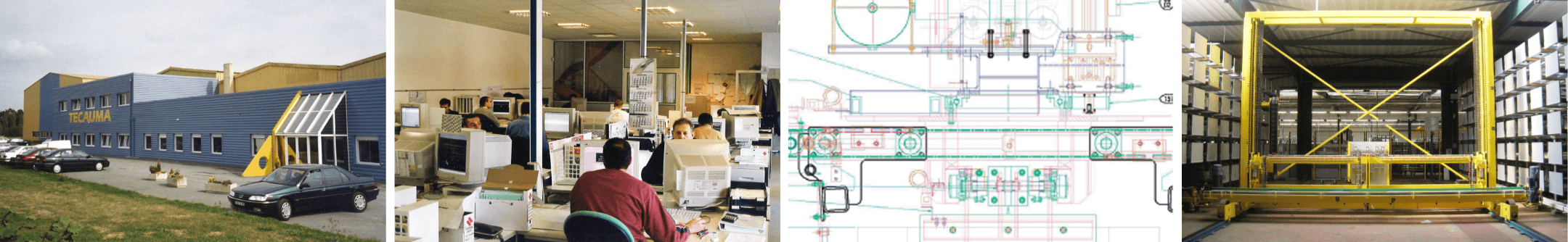

1990 to 2009

1996 - TECAUMA integrates its first FANUC articulated robot for the palletizing of potato crates, created for the Noirmoutier Cooperative.

1997 - The company diversifies into the window & door sector. Its expertise in wood and later furniture opens up opportunities in this market.

2005 - TECAUMA innovates and creates its first system to automatically store window sashes flat, for the company K-LINE.

2008 - TECAUMA develops its first AS/RS (Automated Storage and Retrieval Systems) for long products to store PVC profiles for JANNEAU Menuiseries. TECAUMA is the only French manufacturer of this type of equipment.

2010 to Present

2015 - The Vendée factory expands to 8,000 m² with the construction of a building dedicated to the assembly and testing of AS/RS.

2017 - TECAUMA enters the metallurgy sector, offering its expertise in robotic loading and unloading for machine tools and automated raw material storage.

2020 - The company successfully completes its largest robotics project: a tile manufacturing unit equipped with 23 robots for the TERREAL group.

2024 - Development of the Automated storage system range up to 3T payload capacity to better meet the product and client needs.