Robotflex

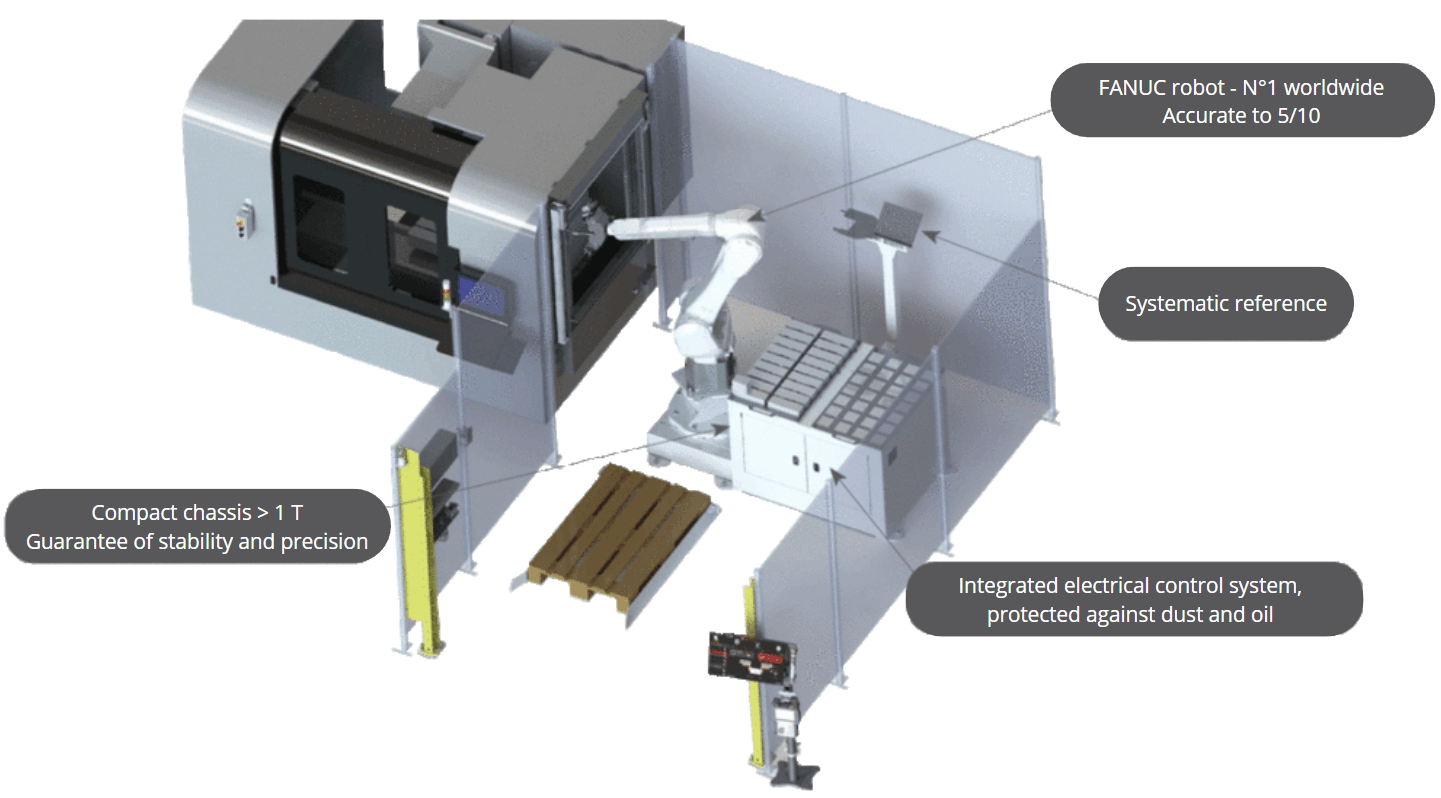

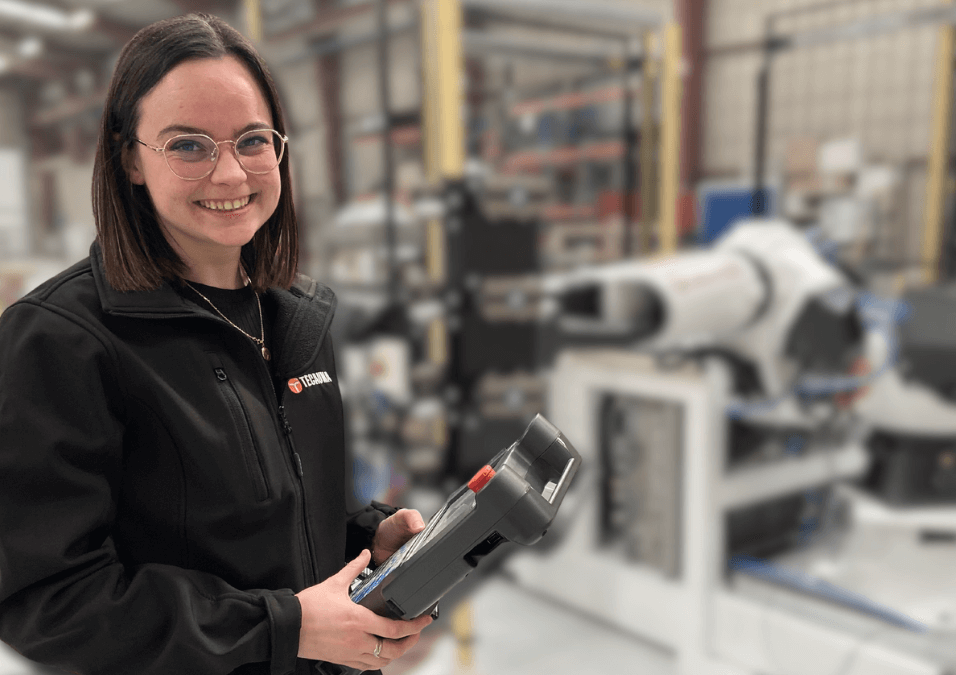

ROBOTFLEX, the range of robots for machine tools, designed by TECAUMA to make machining easier.

TECAUMA has designed its own range of robots in order to load and unload your machine tools, called ROBOTFLEX.

Installed on lathes or machining centers of any brand, ROBOTFLEX automates your production from 5 parts.

The ROBOTFLEX Standard range

With our ROBOTFLEX range, machinists can directly load raw parts into machine tools. This solution is indeed capable of automating all machining phases for a single part.

ROBOTFLEX enables the seamless chaining of machining operations on raw stock of various sizes. This capability allows for the production of small part series while significantly enhancing the cell autonomy. The number of parts per series can range from just a few to several dozen. The robot automatically selects the appropriate machining programs for the machine tool and can also schedule periodic quality checks when needed.

After machining, the ROBOTFLEX robotic arm can flip the machined parts to prepare them for the next operation. By chaining different series, the machine tool spindle can operate for extended periods, potentially running through an entire night of continuous production.

-

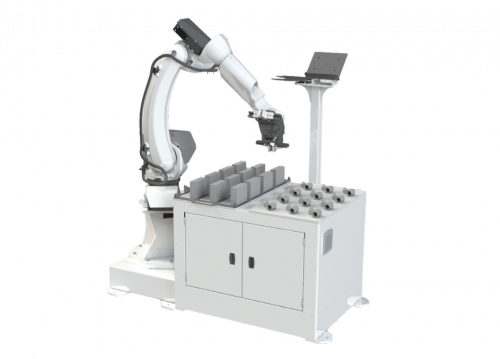

Robotic loading cell for Machining Centers

with ROBOTFLEX CU25 and CU70 - For parts ≤20 kg -

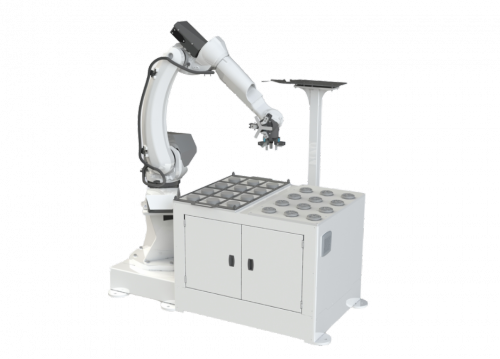

Robotic loading cell for CNC Lathes

with ROBOTFLEX TR25 and TR70 - For parts ≤30 kg

ROBOTFLEX equipment

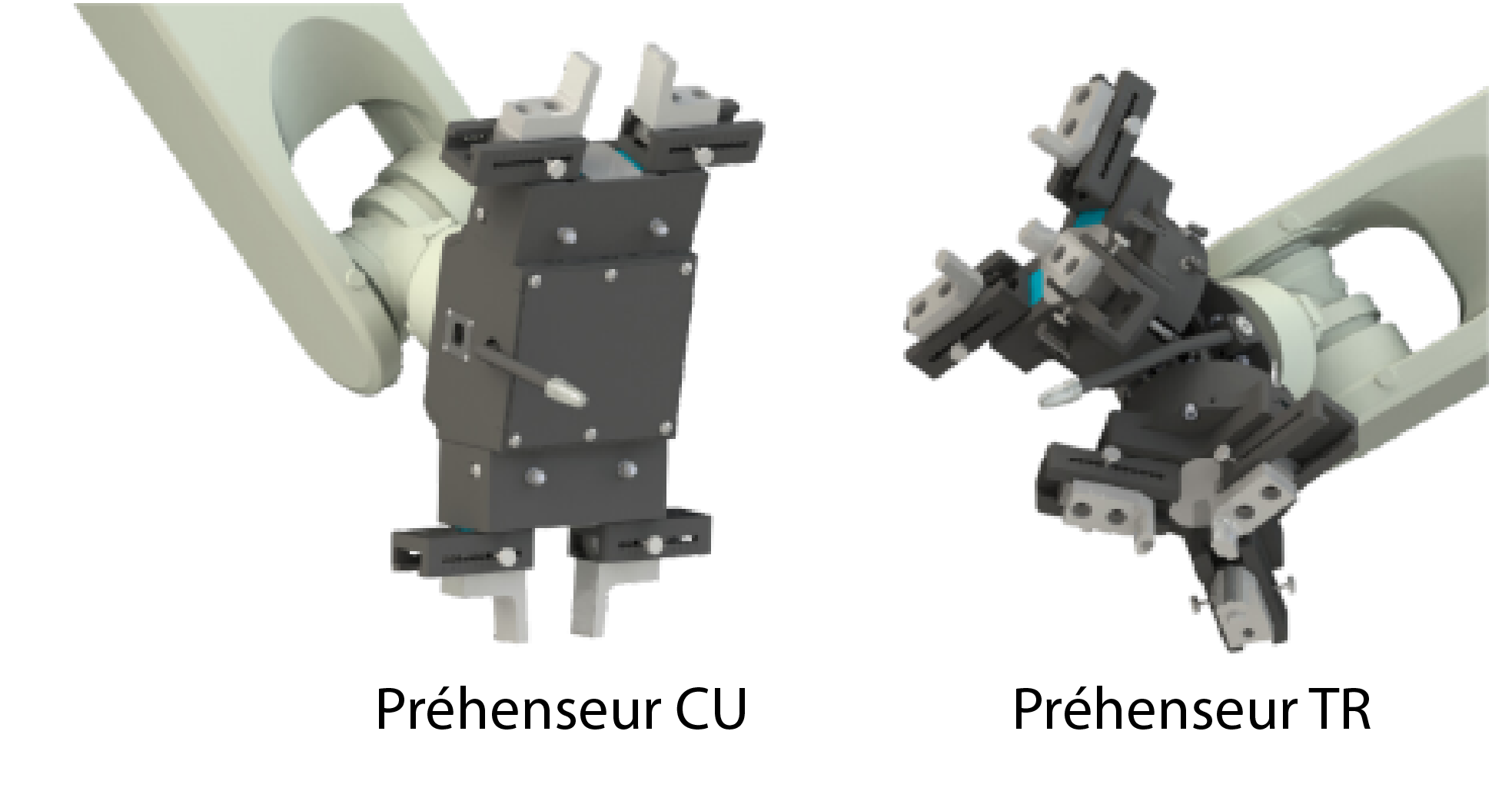

- The Gripper:

- CU gripper equipped with 2 parallel jaw clamps

- TR gripper equipped with concentric jaw clamps

- Tool-free jaw adjustment

- Blow nozzle for cleaning parts

- Interchangeable jaws

- Adjustable pressure on each clamp

- The Interface

- On touch screen

- No need to know robotics

- At each stage: 2 or 3 simple questions

- Recipe creation in less than 15 minutes.

- Change series in less than 10 minutes

- Loading of raw parts

- Using a grid placed on a table

- Using table markings (possibilité of stacking parts)

- From pallet placed on the ground according to options below

- Unloading finished parts onto tables

- In the same locations as the raw parts, on the table

- On pallet according to options below

Options

- Supply of clamping tools for machining centers: "zero point" plate, vice plate, chuck plate

- Dual Spindle Lathe mode: single-spindle operation for loading-unloading 1 part or dual-spindle operation for loading-unloading 2 parts

- Flipping: after operation 1, the part is flipped fo operation 2

- Pick up or put down the parts on pallet using a special pallet on the floor to receive your raw parts and your finished parts

- Put the part down on pallet: placing finished parts on Euro pallets on the ground

- Long bar: special tooling on table to receive your long axes

- Automation of lathe door or side acess curtain

- Network license

- Assistance in the implementation of other parts

The ROBOTFLEX custom range

Do you have a specific need that our standard range does not meet? TECAUMA can offer you custom-made robotic cells, adapted to your needs

-

Robotic Loading Cell for long bars in lathe

The ROBOTFLEX TR 165 S allows you to load long bars which require a huge effort... -

Multifunction Loading Robot for Machining Center

With the ROBOTFLEX CU70 SP robotic cell, load parts directly into the machine with series of different sizes and batches.

What are the advantages of robotizing your production?

What are the advantages of robotizing your production?

- Guarantee the safety of your employees

- Eliminate physical strain

- Compensate for the lack of manpower

- Improve productivity gains

- Gain flexibility

- Ensure consistent and repeatable work

- Highlight your know-how

- Attract talent to your company

ROBOTFLEX, the 100% winning solution to automate your production

- Fits on all brands of machine tools

- For small and medium series

- Quick series changeover: in less than 10 minutes

- Simple and intuitive control interface, no knowledge of robotics is necessary!

- Standard or custom, we adapt our solution to your needs

What do our customer think?

"Here we are dealing with great precision all the time and with ROBOTFLEX,

we no longer hesitate to launch our series of parts every evening

because we are certain to find them the next morning finished and compliant.

In addition, I am very happy to be able to chain milling operations with such loading precision:

the ROBOTFLEX ensures 2/100ths of repositioning without worries".

Mr AMIAUD, FIDEMECA company.

"We are constantly loading the ROBOTFLEX because its implementation is very simple and fast.

The goal: to make the spindle of our 5-axis machining center turn as much as possible.

We do not always have specific 5-axis parts in our order book,

but we load the machine with simpler parts and often for small quantities.

The important thing is to take advantage of this flexible tool to reduce our costs and our delivery times for our customers."

Mr. DROUET, PREMECA company

"We machine parts in large series, with fairly short cycle times.

The ROBOTFLEX has allowed us to free up operators who were only doing machine feeding,

to redirect them towards adjustment/programming. In addition, we have doubled the working time on the robotic center."

Mr. Fabrice MORTELETTE, MORTELETTE company

"These investments were very well received and even eagerly awaited.

The ROBOTFLEX have brought us advantages in terms of autonomy, improved quality, increased load capacity, and flexibility."

Mr. NICOLLEAU, NICOLLEAU Usinage company

Our references