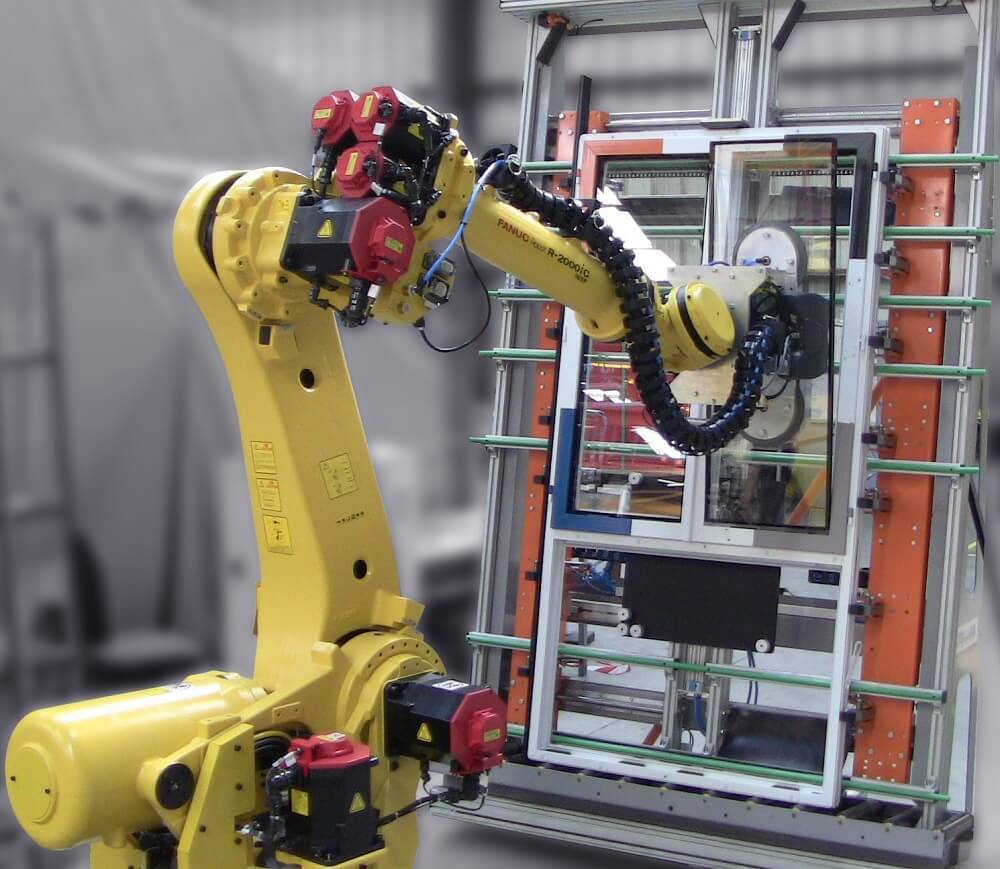

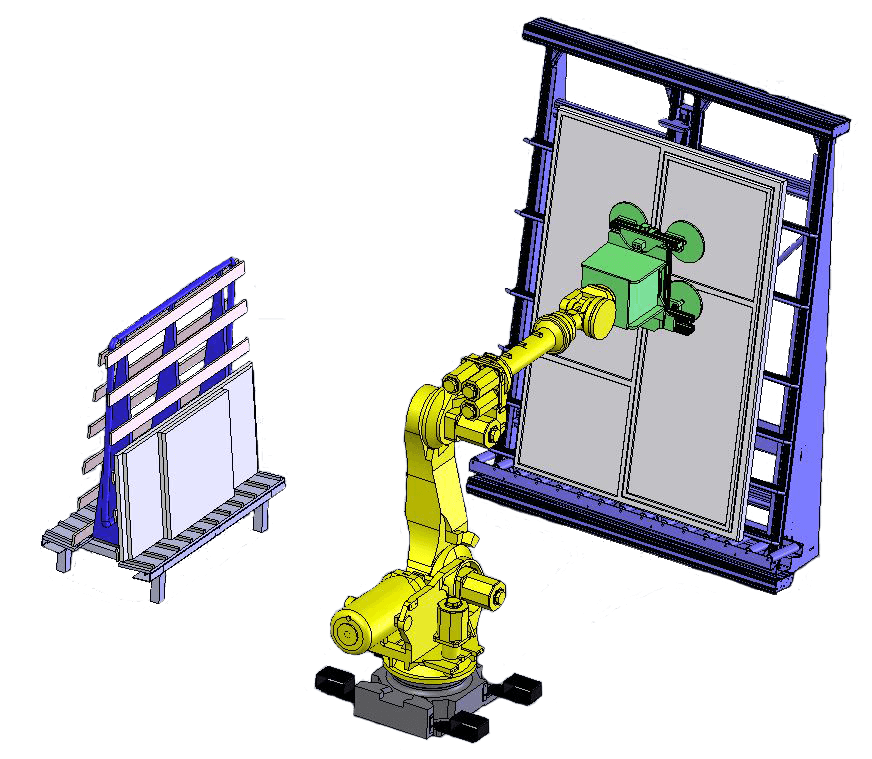

Robotic Glazing cell on assembled window

The robotic glazing cell on assembled window by TECAUMA takes a glass from trolleys or racks and then unloads it automatically in the associated window. The process is the same as for opening sashes (See “Robotic glazing cell on opening sash”) but with the addition of a 3D vision solution to relocate the position of each sash to glaze. Indeed, in this setting, the window frame is flanged but not the opening sashes; it is essential to get rid of the mating clearance, the 3D vision provides an answer to this constraint. In this application, the robot is equipped with a two functions gripper, as the vacuum gripper itself to handle the glasses and the 3D vision. Before setting each glass into a sash, the robot does a scan of the glass with the vision device in order to define the sash position and then to put the corresponding glass in it.

Technical

Features

- For assembled windows, equipped with one or several opening sashes in PVC, Alu or Wood

- Vertical glazing process

- Glasses palletized on trolleys or racks, the palletization plan is communicated to the cell by a barcode reader

- Or glasses delivered one by one on horizontal or vertical conveyor

- Management of integrated glass trolleys (full and empty)

- Ergonomic and intuitive supervision software developed by TECAUMA

- Dimensional limits of frames

- Height: from 400 mm to 2500 mm

- Length: from 400 mm to 3000 mm

- Thickness: from 40 mm to 150 mm

- Maximum weight glazing: 150 kg

_partage_1560256858_