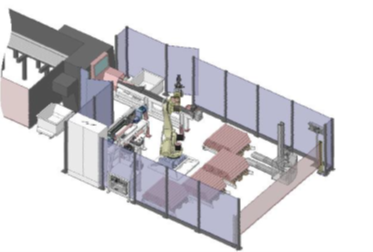

Robotic cell for cutting, drilling and palletizing

An automatic disc saw is combined with a TECAUMA robotic cell, performing the successive functions of bar marking, drilling, and then palletizing. The poly-articulated robot, at the heart of the solution, carries out all the handling operations between the different stations.

The flexibility of the solution allows for the processing of products of various sizes with associated palletizing patterns.

The assembly, including the saw, is controlled by a common, intuitive and ergonomic HMI.

This robotic solution guarantees production quality (repeatability of operations), product traceability and clean and organized packaging of finished parts.

Technical

Features

FANUC 6-axis robot

Interchangeable magnetic grippers, on automatic tool changer, depending on the diameters of the bars to be handled

Dot peen engraving station, on saw output conveyor

Automatic drilling bench, on an independent frame, equipped with two spindles, for drilling

Dimensions of the treated products:

- Round Steel Bars

- Diameter: minimum 20 to maximum 85 mm

- Length: minimum 100 mm to maximum 1,000 mm

Engraving station:

- Mini bar diameter ≥ 30 mm

- Poids maxi : 70 kg

Chamfering bench:

- Center points Ø5 to Ø10mm in 0.5mm steps (max. depth 12 mm)

Palletizing locations:

- 4 Europe palettes 800 × 1 200 mm

Ergonomic and intuitive interface for cell parameterization

_partage_1560256858_