07/05/2022

TECAUMA offers glazing manufacturers robotic cells for the automatic packaging of glazing, which can be integrated at the end of existing lines.

>>> TECAUMA brings its expertise and solutions to your manufacturing process automation issues.

Challenge

Search for a tailor-made solution to reduce difficult working conditions and ensure the safety of operators in charge of packaging glazing.

At the end of glazing assembly lines, conventional packaging grippers used by operators, create "bottlenecks".

Glazing handling is dangerous and restrictive..

Solution provided by TECAUMA

TECAUMA offers glazing manufacturers, robotic cells for the automatic packaging of glazing, which can be integrated at the end of existing lines.

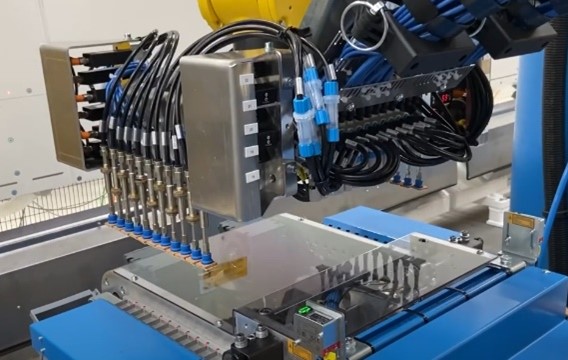

> A first robot deposits the protective "cork pads" on the glazing. The robot places the necessary number of pads, in the right place, according to the size of the next glazing which will be supported. This intelligent process, patented by Tecauma, reduces the consumption of pads and ensures maximum protection of the glazing during handling and transport.

> A second robot picks up the glazing and stacks it on trolleys, pallets or racks using a gripper with suction cups that can be selected automatically according to the dimensions of the glazing.

In order not to stop the assembly line, this stacking robot has 2 drop zones:

- A loading area

- An area in the process of evacuation of a full trolley and introduction of an empty trolley.

Resultats

After a first robot put into service at a French glazing manufacturer factory and building on the success of this robot and the maturity of the market, other robotic cells have been ordered and will soon be installed at other glazing manufacturers factories.