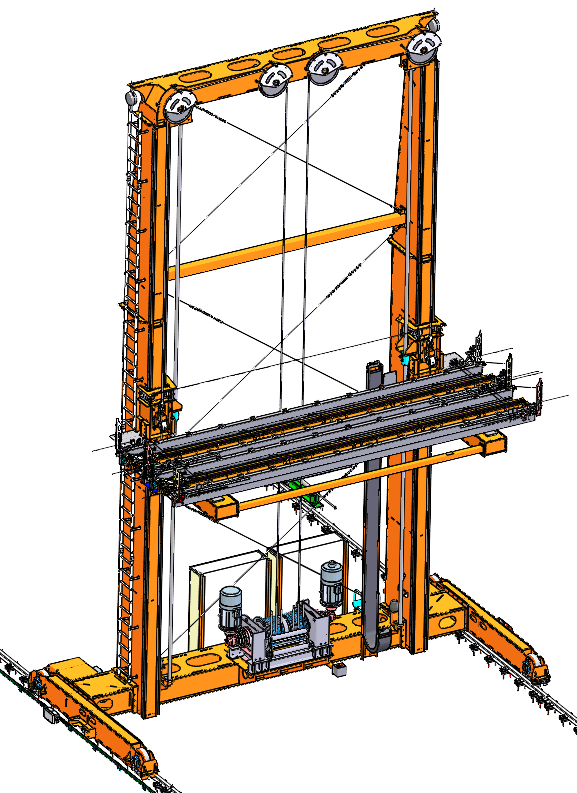

STACKER CRANE WITH DOUBLE CONVEYOR

TEC’UP H14D is equipped with a double conveyor in order to be better adapted to processes with control and preparation areas, such as « lacquering » and « thermal break assembly ». TEC’UP H8 et H12 are equipped with a single conveyor, and respond to processes used to supply machining areas.

TEC’UP stacker cranes, developed by TECAUMA, automate the storage of raw materials (tubes, bars, profiles). TEC’UP Automated Storage and Retrieval Systems are adapted to the building, in order to optimize space by making the best use of the available volume.

Dynamic storage limits manual handling: the material is automatically made available to operators thanks to picking stations adapted to the type of product to be picked. The raw material feed time to the machines is thus shortened.

Raw material management is improved by the computer system, which makes it possible to know the stock in real time, to record consumption, and thus to achieve an optimization of the supply.

Finally, all the products are stored in the same place, sheltered from bad weather.

Technical

Features

- For the following products (tubes, bars, profiles), with a standard length of 6500 mm (7000mm on request)

- Products packaged in stretchers, in bundles or in bulk

- Maximum weight of container and products: 1300 kg approximatively

- Minimum width required in the building:

- 1 shelving: 17m

- 2 shelving : 24m

- Lenght required in the building depending on the need.

- Max height available in the building: 14m

- Customized loading stations for products depending on the flow and tools: forklift, overhead crane…

- Output stations can be customized according to production stations to supply

- Ergonomic and intuitive supervision software developed by TECAUMA

- Associated IT functions such as: stock mapping, inventory function…

- Service and maintenance contracts

_partage_1560256858_