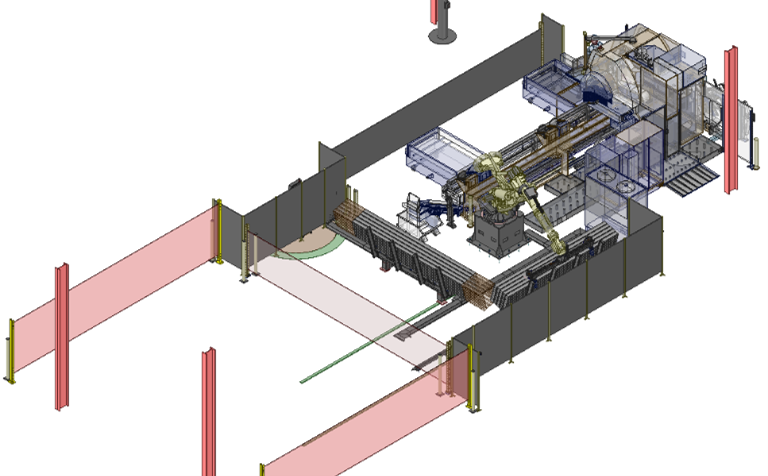

Robotization at the tube laser cutting output

A large-scale poly-articulated robot is installed at the back of the output bench of a tube laser cutting machine. It ensures the unit pick-up of each tube, the vertical placement for the evacuation of the cutting pads, then the packing in the process on pallets or rafters.

It allows the palletization of two different tubes (two respective packages) in the same production series.

The robot's location at the back of the bench also allows the machine to be operated manually. In this case, the robot is folded into position and stopped. Finally, the HMI is intuitive and ergonomic. It allows the creation of recipes, easily and quickly.

Technical

Features

Independently digitized gripper for positioning according to the length of the tube and its cut-outs

Two independent and versatile packing stations, to receive a pallet or wooden rafters

Cutting pad evacuation station

Ergonomic and intuitive interface for controlling the robot cell

For square or rectangular tubes

Dimensions of the treated tubes:

- Section mini: 60 x 60 mm

- Section max: 180 x 180 mm

- Minimum length: 1,000 mm

Maximum weight of the tubes:

- 120 kg

- Maximum length: 6,000 mm

_partage_1560256858_