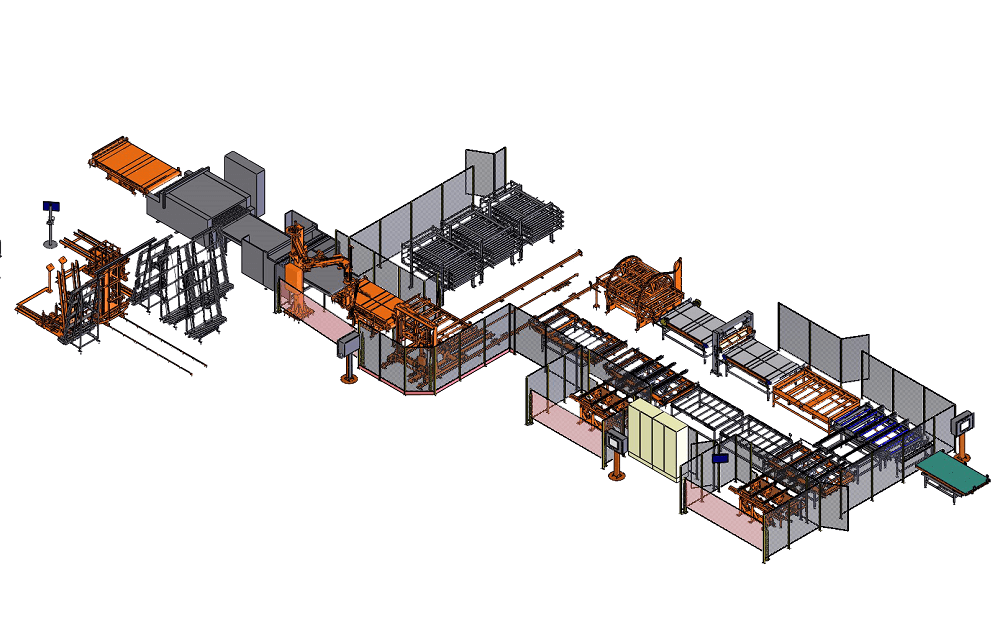

FRONT DOOR ASSEMBLY LINE

TECAUMA produces production lines for aluminium, wooden and PVC doors. Each line is customized according to both the customer’s products and assembly process. Gluing and calendering stations are implemented for monobloc type aluminium doors. The handling conveyors are designed according to the product material, and can be made of rollers, belts or bands.

Ergonomic stations make it possible to automatically turn side of doors or to present the doors vertically in front of the operators for finishing tasks.

Technical

Features

- Gluing by automatic application of glue or double-sided tape.

- Finishing stations for customizing doors.

- Integration of handling or gluing robots

- Storage of work in progress in buffer(s) (horizontal, vertical)

- Integration of the bagging or packaging process

- Ergonomic and intuitive supervision software developed by TECAUMA

- For all standard and custom doorsets; aluminium, steel and wood

- Dimensional limits of door units:

- Height: from 1700 to 2500 mm

- Width : from 700 to 1250 mm

- Thickness : from 45 to 240 mm

- Maximum weight of a door unit: 150kg

_partage_1560256858_